Digital Printing vs Offset Ink Printing: What's the Difference?

- Share

- publisher

- DHP-Julie

- Issue Time

- Aug 21,2025

Summary

Discover the key differences between digital printing and offset ink printing, and how each method impacts the production of custom packaging boxes. Learn which option is best suited for your project based on cost, quality, and customization needs.

Introduction

In the world of printing, digital printing and offset ink printing are two of the most commonly used methods. Each has distinct advantages depending on your project needs, whether you’re printing small batches or large-scale runs. This article explores the differences between digital and offset printing, helping you understand which method is best suited for your business. At DHP Factory, we specialize in providing high-end custom packaging solutions, including both digital and offset printing techniques to bring your brand vision to life.

Digital Printing: A Modern Approach

What is Digital Printing?

Digital printing uses electronic files, such as PDFs, to print directly onto the substrate. The process eliminates the need for printing plates, which reduces setup time and costs. Digital printing is ideal for projects requiring high-quality, short-run prints or personalized items.

Benefits of Digital Printing

• Fast Turnaround Time: As no physical plates are needed, digital printing is quicker, making it suitable for rush orders.

• Customization: Digital printing allows for variable data printing, where each print can be uniquely customized, making it perfect for personalized packaging solutions.

• Lower Costs for Small Runs: Digital printing eliminates the initial setup costs associated with offset printing, making it more cost-effective for short-run jobs.

• Environmentally Friendly: With less waste material compared to offset printing, digital printing is more eco-friendly, aligning with our commitment at Packprince to provide sustainable packaging options.

When to Choose Digital Printing?

• Small Runs: If you need fewer than 500 copies, digital printing is the best option.

• Personalized Packaging: Digital printing excels in offering personalized details like names, messages, and unique designs.

• Quick Turnaround: For projects with tight deadlines, digital printing is an efficient choice.

Digital Printing Machine

Heidelberg Printing Machine

Offset Ink Printing: The Traditional Technique

What is Offset Printing?

Offset printing is a more traditional method that uses plates to transfer ink onto a substrate. It is widely regarded for its ability to produce high-quality prints, especially in large quantities. The process involves creating a plate for each color used in the design, which is then pressed onto the paper or packaging material.

Benefits of Offset Printing

• High-Quality Output: Offset printing produces sharp, clean images and is especially known for achieving accurate color reproduction.

• Cost-Effective for Large Runs: While it involves a higher initial setup cost, offset printing becomes more cost-effective as the print volume increases.

• Versatile: Offset printing can print on a variety of materials, including paperboard, plastic, and more, making it an excellent choice for custom packaging solutions.

• Consistency: Offset ensures consistent color quality and clarity, which is crucial for brands that need precise and uniform packaging designs.

When to Choose Offset Printing?

• Large Runs: If you are printing thousands of items, offset printing is more economical.

• High-Quality and Precision: Offset is ideal for projects requiring exact color matching and high-end detail.

• Variety of Materials: If your packaging requires printing on various materials or thicker substrates, offset printing is a better option.

Key Differences Between Digital and Offset Printing

| Feature | Digital Printing | Offset Printing |

| Setup Costs | Low initial setup, cost-effective for short runs. | High initial setup, ideal for large runs. |

| Print Quality | High quality, but less precise than offset. | Exceptional quality with precise color matching. |

| Turnaround Time | Fast; no plates involved. | Slower; requires setup of printing plates. |

Customization | Perfect for personalized items. | Better for uniform, large runs. |

Cost Efficiency | Economical for small batches. | Most cost-effective for bulk production. |

Material Options | Limited in material variety. | Can print on a wide variety of substrates. |

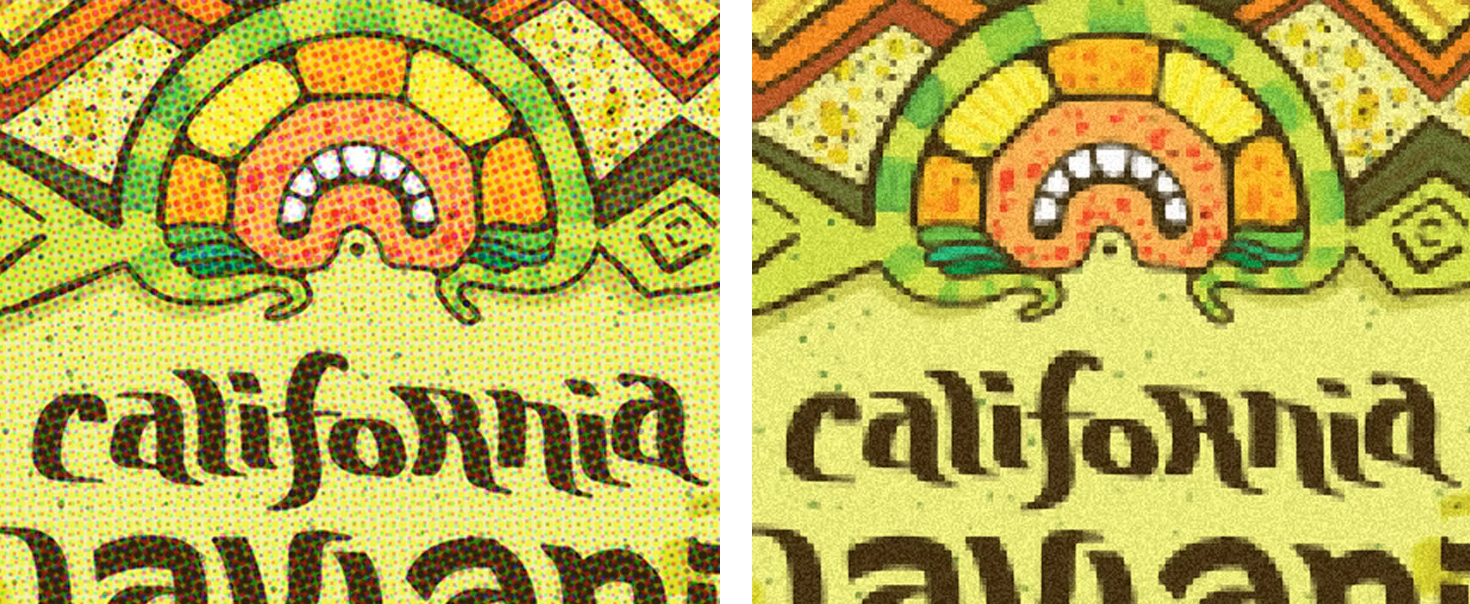

Offset Ink Printing

Digital Printing

Offset Ink Printing

Digital Printing

Why DHP Factory Chooses the Best of Both Worlds?

At DHP Factory, we specialize in providing high-end, customized packaging solutions. Our expertise spans both digital and offset printing, allowing us to offer the best printing method for every project.

Why You Should Consider Our Printing Services?

Custom Designs: Whether it’s digital or offset, we tailor each design to reflect your brand’s uniqueness.

• Eco-Friendly: We prioritize sustainability by offering eco-friendly packaging options using both printing methods.

• High-Quality Standards: With over 10 years in the industry, our team ensures top-notch quality, from initial design to final production.

• Global Reach: We have successfully served high-end brands across Europe and North America, providing exceptional packaging solutions that align with global market trends.

Conclusion

Both digital and offset ink printing offer distinct advantages, and the best choice depends on the specific needs of your project. Whether you’re printing custom packaging for a small batch or need high-volume production, DHP Factory is equipped to deliver the highest quality and most cost-effective solutions. Contact us today to discuss your next packaging project and find out how our digital and offset printing services can elevate your brand.